TEDCOM emerged as an initiative by several entrepreneurs to implement liquid infusion technology for the Aerospace sector in Andalusia.

IDEC, a European leader in the development and application of RTM technology, is one of its key promoters, contributing its expertise and experience inAdvanced Composite Solutionsusing out-of-autoclave liquid infusion processes for the development ofComplex Aerostructures.

Leveraging extensive knowledge of materials and RTM technology, we offer innovative and competitive solutions that enhance performance and service life.

At TEDCOM, we aim to capitalize on our capabilities and explore product diversification pathways to meet market demands. Key target sectors in our strategy include NAVAL, DEFENSE, and AUTOMOTIVE industries.

To achieve this, we are fully equipped with the necessary human and technical resources. Our personnel have been trained in the development of complex processes to produce composite components using RTM technology for high-rate production series. Additionally, our expertise in design engineering and composite material production is one of our core assets.

Sustainability and environmental protection are fundamental principles for us. We are committed to proactively respecting the environment by implementing all available measures to ensure eco-friendly practices.

We have obtained the Unified Environmental Authorization (A.A.U.) from the Andalusian Regional Ministry of Environment, enabling us to carry out our activities within the privileged setting of the TECNOBAHÍA Technology Park.

PRODUCTS

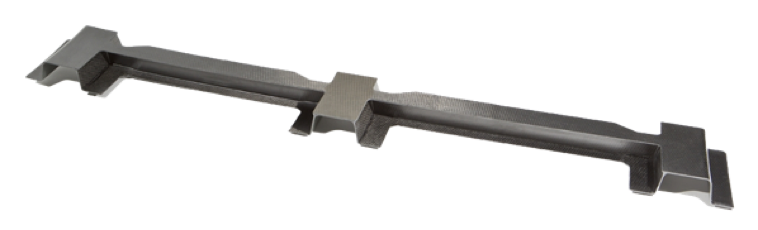

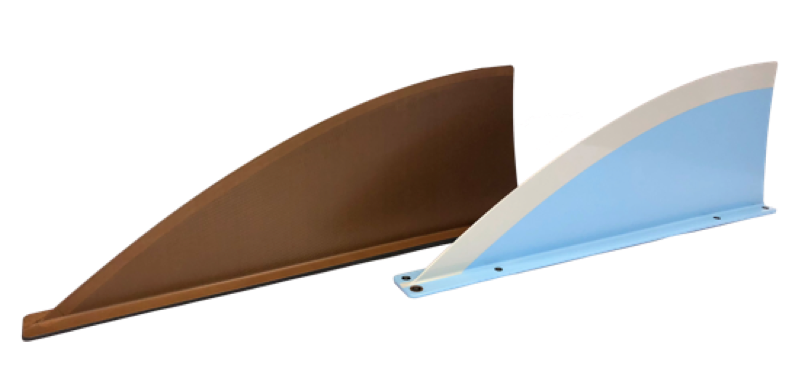

TEDCOM focuses its production on a significant project for AIRBUS DEFENCE AND SPACE, manufacturing BEAMS and STRAKES for the FAN COWLS of the AIRBUS A320 NEO1.These components are highly complex to manufacture, achieved through substantial innovation and development efforts by one of TEDCOM's promoting partners, IDEC

The production of these components represents a new generation of structural elements for Fan Cowls, offering improved solutions compared to current ones, which are metallic in some cases. This project demonstrates TEDCOM's expertise in advanced composite solutions and RTM (Resin Transfer Molding) technology.

TEDCOM’s participation in the A320NEO program is considered challenging and future-oriented, positioning TEDCOM competitively in the aeronautics sector

This project has allowed TEDCOM to transition from a small office to having significant production facilities, establishing a strong production capacity.The company's involvement in the A320 NEO program showcases its ability to provide innovative and competitive solutions in the aerospace industry, focusing on weight reduction and cost improvements

Armoring Equipment Structures